Parts made of laminate composite materials pose an inspection challenge due to their various shapes and thicknesses. | The new OmniScan MX2 UT2 module from Olympus represents a powerful, yet affordable solution for TOFD inspection. Spectrum has been serving compounders and scientists for nearly five decades, and we've earned the trust of quality-driven industries by continually investing in our infrastructure, instrumentation, regulatory compliance and personnel. The OmniScan MX2 offers a high acquisition rate and new powerful software features for efficient manual and automated inspection performanceall in a portable, modular instrument. Learn more about our OmniScan MX2 solutions.  These wedges are available in various longitudinal refracted angles and can be ordered for specific diameters, or from a kit covering the complete diameter range.

These wedges are available in various longitudinal refracted angles and can be ordered for specific diameters, or from a kit covering the complete diameter range.  Featuring the industry-standard phased array user interface with faster-than-ever performance, a bigger and brighter 10.4 in.

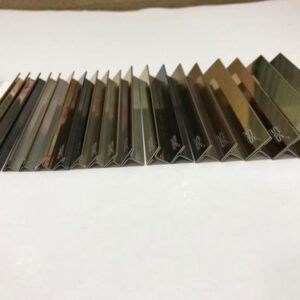

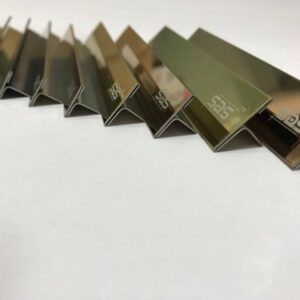

Featuring the industry-standard phased array user interface with faster-than-ever performance, a bigger and brighter 10.4 in.  Intelligent layouts for configuring up to 8 groups. They offer several advantages, including: The new stainless steel wedges (on the left) have a shorter approach by 3 mm for better coverage. All our U.S. chemical manufacturing facilities are ISO 9001:2015 certified. A selection of current Urnex, Puro and Biocaf SDS can be found below. Should you require SDS for other products or for countries outside of the United States, please contact us at info@urnex.com with your request. Careers Olympus has a wide range of scanners to address fabrication or maintenance weld inspections needs. Through this dedication, we have earned the trust of tens of thousands of loyal customers. The IHC wedge option can be ordered to improve the quality of the inspection: irrigation, mounting holes for the wedge holder to work with any Olympus scanner, and carbide pins to increase wear resistance. Screen shot example of a Product Detail Page (Safety Data Sheet link is highlighed withred arrow): If you are unable to locate a specific SDS, please contact Spectrum at 1-800-370-6231, Option 2, Option 2 or emailsds@spectrumchemical.com. Safety Data Sheets aids in the selection of safe products, helps employers and employees understand the potential health and physical hazards of a chemical and describes how to respond effectively to exposure situations. As a world leader in phased array technology, Olympus has released a new line of modules compatible with MX2 instrument. COMPOSITION / INFORMATION ON INGREDIENTS HAZARDOUS INGREDIENT(S) CAS # WEIGHT % DISTILLATES (PETROLEUM) HYDROTREATED LIGHT WHITE MINERAL OIL POLYDIMETHYLSILOXANE LIQUEFIED PETROLEUM GAS 64742-47-8 8042-47-5 63148-62-9 68476-86-8 10.0-20.0 2.5-10.0 1.0-2.5 10.0-20.0 EXACT PERCENTAGES ARE BEING WITHHELD AS TRADE SECRET INFORMATION. All Rights Reserved. Higher voltage (up to 340 V) eliminates the need for preamplifiers, Better wear resistance without the hassle of carbide wear pin adjustments, Better coupling as carbide wear pins can lift the wedge from the surface, Shorter approach (by 3 mm) for better coverage of the top of the weld. Extensive readings database and predefined lists for trigonometry, flaw statistics on axes, volumetric position information, code-based acceptance criteria, corrosion mapping statistics, etc. In the effort for continuous improvement, the software interface was simplified and the response time optimized in order to provide the best experience possible for customers. For the best experience on our site, be sure to turn on Javascript in your browser. Immersion probes are designed to be used with a water wedge or in an immersion tank when the test part is partially or wholly immersed. It is also very easy to create a setup right in the OmniScan, thanks to the following features: Thanks to NDT SetupBuilder and OmniPC campanion software, the OmniScan MX2 can be dedicated exclusively to calibration and acquisition tasks or, if preferred, can perform all the steps of an inspection, right on its large, user-friendly touch screen. | Terms Of Use | Privacy Notice |

Intelligent layouts for configuring up to 8 groups. They offer several advantages, including: The new stainless steel wedges (on the left) have a shorter approach by 3 mm for better coverage. All our U.S. chemical manufacturing facilities are ISO 9001:2015 certified. A selection of current Urnex, Puro and Biocaf SDS can be found below. Should you require SDS for other products or for countries outside of the United States, please contact us at info@urnex.com with your request. Careers Olympus has a wide range of scanners to address fabrication or maintenance weld inspections needs. Through this dedication, we have earned the trust of tens of thousands of loyal customers. The IHC wedge option can be ordered to improve the quality of the inspection: irrigation, mounting holes for the wedge holder to work with any Olympus scanner, and carbide pins to increase wear resistance. Screen shot example of a Product Detail Page (Safety Data Sheet link is highlighed withred arrow): If you are unable to locate a specific SDS, please contact Spectrum at 1-800-370-6231, Option 2, Option 2 or emailsds@spectrumchemical.com. Safety Data Sheets aids in the selection of safe products, helps employers and employees understand the potential health and physical hazards of a chemical and describes how to respond effectively to exposure situations. As a world leader in phased array technology, Olympus has released a new line of modules compatible with MX2 instrument. COMPOSITION / INFORMATION ON INGREDIENTS HAZARDOUS INGREDIENT(S) CAS # WEIGHT % DISTILLATES (PETROLEUM) HYDROTREATED LIGHT WHITE MINERAL OIL POLYDIMETHYLSILOXANE LIQUEFIED PETROLEUM GAS 64742-47-8 8042-47-5 63148-62-9 68476-86-8 10.0-20.0 2.5-10.0 1.0-2.5 10.0-20.0 EXACT PERCENTAGES ARE BEING WITHHELD AS TRADE SECRET INFORMATION. All Rights Reserved. Higher voltage (up to 340 V) eliminates the need for preamplifiers, Better wear resistance without the hassle of carbide wear pin adjustments, Better coupling as carbide wear pins can lift the wedge from the surface, Shorter approach (by 3 mm) for better coverage of the top of the weld. Extensive readings database and predefined lists for trigonometry, flaw statistics on axes, volumetric position information, code-based acceptance criteria, corrosion mapping statistics, etc. In the effort for continuous improvement, the software interface was simplified and the response time optimized in order to provide the best experience possible for customers. For the best experience on our site, be sure to turn on Javascript in your browser. Immersion probes are designed to be used with a water wedge or in an immersion tank when the test part is partially or wholly immersed. It is also very easy to create a setup right in the OmniScan, thanks to the following features: Thanks to NDT SetupBuilder and OmniPC campanion software, the OmniScan MX2 can be dedicated exclusively to calibration and acquisition tasks or, if preferred, can perform all the steps of an inspection, right on its large, user-friendly touch screen. | Terms Of Use | Privacy Notice |  OmniPC | Select SDS product information to view/download : To view and print this information, you'll need a PDF reader like Adobe Acrobat Reader installed on your computer -Get Adobe Acrobat Reader. | Subscribe to the Olympus IMS Newsletter, an e-newsletter that will keep you posted on special offers, new products, or applications. California SB258 sheets are available on the individual product pages. In addition, this system detects mid-wall damage, such as hydrogen-induced blistering and manufacturing-induced delamination, and clearly differentiates such anomalies from loss-of-wall-thickness. Depending on your connection speed, it could take a few minutes.

OmniPC | Select SDS product information to view/download : To view and print this information, you'll need a PDF reader like Adobe Acrobat Reader installed on your computer -Get Adobe Acrobat Reader. | Subscribe to the Olympus IMS Newsletter, an e-newsletter that will keep you posted on special offers, new products, or applications. California SB258 sheets are available on the individual product pages. In addition, this system detects mid-wall damage, such as hydrogen-induced blistering and manufacturing-induced delamination, and clearly differentiates such anomalies from loss-of-wall-thickness. Depending on your connection speed, it could take a few minutes.  Powerstart your day with the OmniScan MX2. With its very slim design, this manual scanner is able to inspect pipes in areas with limited access. You can be confident that you will get the most out of your investment as specifications will continue to evolve with your needs through constant software updates. OmniPC software is the most efficient and affordable option for PC-based OmniScan data analysis, and features the same analysis and reporting tools provided in the OmniScan onboard software. Careers The OmniScan flaw detectors provide powerful inspection capabilities for manual and automated applications. The above mentioned software improvements are also incorporated into the OmniPC software allowing users to analyze data on a PC, while the OmniScan can be redeployed for other data acquisition jobs. Do not spray on an open flame or other ignition source. The Globally Harmonized System (GHS) is a system for standardizing the classification and labeling of chemicals.

Powerstart your day with the OmniScan MX2. With its very slim design, this manual scanner is able to inspect pipes in areas with limited access. You can be confident that you will get the most out of your investment as specifications will continue to evolve with your needs through constant software updates. OmniPC software is the most efficient and affordable option for PC-based OmniScan data analysis, and features the same analysis and reporting tools provided in the OmniScan onboard software. Careers The OmniScan flaw detectors provide powerful inspection capabilities for manual and automated applications. The above mentioned software improvements are also incorporated into the OmniPC software allowing users to analyze data on a PC, while the OmniScan can be redeployed for other data acquisition jobs. Do not spray on an open flame or other ignition source. The Globally Harmonized System (GHS) is a system for standardizing the classification and labeling of chemicals.  Continue rinsing for at least 15 minutes. Please refer to the videos below for information on some of the key changes: Let us provide you with the cleaning chemical support that will deliver the very best results for your budget. You have already flagged this document.Thank you, for helping us keep this platform clean.The editors will have a look at it as soon as possible. FREE SHIPPING in the Continental US on all orders of $30 or more! Manual and Semiautomated endobj

6 0 obj

<>stream

Terms & Conditions

Cookie Settings Your needs Even if you choose a motorized or manual type, you will be amazed by their versatility, dependability and repeatability. Now, TOFD PCS calibration and lateral wave straightening can be performed automatically. The capacity to accurately position probes according to the surface being inspected greatly influences inspection quality. Urnex Brands, LLC. IF SWALLOWED: Immediately call a poison center or physician. IF ON SKIN: Wash with plenty of water.

Continue rinsing for at least 15 minutes. Please refer to the videos below for information on some of the key changes: Let us provide you with the cleaning chemical support that will deliver the very best results for your budget. You have already flagged this document.Thank you, for helping us keep this platform clean.The editors will have a look at it as soon as possible. FREE SHIPPING in the Continental US on all orders of $30 or more! Manual and Semiautomated endobj

6 0 obj

<>stream

Terms & Conditions

Cookie Settings Your needs Even if you choose a motorized or manual type, you will be amazed by their versatility, dependability and repeatability. Now, TOFD PCS calibration and lateral wave straightening can be performed automatically. The capacity to accurately position probes according to the surface being inspected greatly influences inspection quality. Urnex Brands, LLC. IF SWALLOWED: Immediately call a poison center or physician. IF ON SKIN: Wash with plenty of water.  OmniScan MXU Software Version 5.9: User's Manual, OmniScan MXU Software Version 4.4: User's Manual, Lithium-Ion Batteries for the OmniScan: Maintenance Guide, Austenitic, Nickel, and Other Coarse Grain Alloy, Case Study: Inspecting Boiler Tube Welds Using the COBRA Ultrasonic Phased Array Solution Instead of Radiography, Ahead of the Curve: UT is Finally Flexible Enough for Pipe Elbow Inspection, 5 Advantages Pipecheck Analyze Software Brings to Routine Corrosion Monitoring, 4 Benefits of OmniScan Softwares Updated DGS Functionality, 4 New Features of the OmniScan MXU 4.4 Software that Help Speed-Up Inspections, Solving Austenitic/Dissimilar Weld Inspection Challenges, Get the latest on recent advances in portable phased array, 325 mm x 235 mm x 130 mm (12.8 in. Safety Data Sheets (SDS) are required by law for many chemicals.

OmniScan MXU Software Version 5.9: User's Manual, OmniScan MXU Software Version 4.4: User's Manual, Lithium-Ion Batteries for the OmniScan: Maintenance Guide, Austenitic, Nickel, and Other Coarse Grain Alloy, Case Study: Inspecting Boiler Tube Welds Using the COBRA Ultrasonic Phased Array Solution Instead of Radiography, Ahead of the Curve: UT is Finally Flexible Enough for Pipe Elbow Inspection, 5 Advantages Pipecheck Analyze Software Brings to Routine Corrosion Monitoring, 4 Benefits of OmniScan Softwares Updated DGS Functionality, 4 New Features of the OmniScan MXU 4.4 Software that Help Speed-Up Inspections, Solving Austenitic/Dissimilar Weld Inspection Challenges, Get the latest on recent advances in portable phased array, 325 mm x 235 mm x 130 mm (12.8 in. Safety Data Sheets (SDS) are required by law for many chemicals.  Store locked up. The new conventional ultrasound module features the same UT-channel technology as the PA2 modules, but offers twice as many channels. Shop all of our brands in one cart. They are particularly helpful when testing cladded pipes or highly attenuating materials. HAZARD(S) IDENTIFICATION CLASSIFICATION: FLAMMABLE AEROSOLS (CATEGORY 1), ASPIRATION HAZARD (CATEGORY 1), EYE IRRITATION (CATEGORY 2B) LABEL ELEMENTS SIGNAL WORD: DANGER PICTOGRAMS: FLAME, HEALTH HAZARD HAZARD STATEMENTS: EXTREMELY FLAMMABLE AEROSOL. Leadingclass signal-to-noise ratio provides optimum data quality for TOFD inspection. Group copy option for fast multiple-group configuration. The scanners can be mounted on pipes and flat surfaces and are easy to use for fast detection of defect from manufacturing induced lamination to in-service wall thickness reduction. Over the last few years Olympus has devoted considerable effort to innovating and deploying a wide range of complete market solutions aimed at meeting customers needs. 3. Sitemap. These wedges are designed to perform manual scans and to accommodate the Mini-Wheel encoder.

Store locked up. The new conventional ultrasound module features the same UT-channel technology as the PA2 modules, but offers twice as many channels. Shop all of our brands in one cart. They are particularly helpful when testing cladded pipes or highly attenuating materials. HAZARD(S) IDENTIFICATION CLASSIFICATION: FLAMMABLE AEROSOLS (CATEGORY 1), ASPIRATION HAZARD (CATEGORY 1), EYE IRRITATION (CATEGORY 2B) LABEL ELEMENTS SIGNAL WORD: DANGER PICTOGRAMS: FLAME, HEALTH HAZARD HAZARD STATEMENTS: EXTREMELY FLAMMABLE AEROSOL. Leadingclass signal-to-noise ratio provides optimum data quality for TOFD inspection. Group copy option for fast multiple-group configuration. The scanners can be mounted on pipes and flat surfaces and are easy to use for fast detection of defect from manufacturing induced lamination to in-service wall thickness reduction. Over the last few years Olympus has devoted considerable effort to innovating and deploying a wide range of complete market solutions aimed at meeting customers needs. 3. Sitemap. These wedges are designed to perform manual scans and to accommodate the Mini-Wheel encoder.

x `E \U}Lg&3drL !K>%H$

"7KDEw[ 0D\zsY2 AzFYPPK#w98nYYY B7~/f:b -P{6T8*?Bt:lVyiS?Z?uB93xWpadU6l,Mp^_x:k

a ?G>R_=&|Of6vx^AGixj:Zj+ hO_a Ncp&Ew

hZnRdB#uwI:4K}+)g>w+ 4YQc$3Ws-OSGj@

W$*LN

OChc~_+z}5tiGhsu: P*F5pe5z1@ Sorry, this page is not available in your country. NDT SetupBuilder Our A24 probe series for manual contact inspection incorporates an ergonomic case design, replaceable membrane, and large square aperture to work in a variety of applications. These solutions are based on the OmniScan flaw detector, the GLIDER scanner, and dedicated probes and wedges designed for CFRP flat panel and radius inspection.

x `E \U}Lg&3drL !K>%H$

"7KDEw[ 0D\zsY2 AzFYPPK#w98nYYY B7~/f:b -P{6T8*?Bt:lVyiS?Z?uB93xWpadU6l,Mp^_x:k

a ?G>R_=&|Of6vx^AGixj:Zj+ hO_a Ncp&Ew

hZnRdB#uwI:4K}+)g>w+ 4YQc$3Ws-OSGj@

W$*LN

OChc~_+z}5tiGhsu: P*F5pe5z1@ Sorry, this page is not available in your country. NDT SetupBuilder Our A24 probe series for manual contact inspection incorporates an ergonomic case design, replaceable membrane, and large square aperture to work in a variety of applications. These solutions are based on the OmniScan flaw detector, the GLIDER scanner, and dedicated probes and wedges designed for CFRP flat panel and radius inspection.  | Phased array, TOFD, and conventional ultrasonic techniques can be used alone or in combination to achieve full-weld coverage with high probability of detection. The OmniScan PA system with the HydroFORM scanner is designed to offer the best inspection solution for detecting wall-thickness reductions resulting from corrosion, abrasion, and erosion. OmniPC is a new software program that benefits form the same user interface and analysis and reporting features as the OmniScan with the added flexibility to be run on a personal computer. The OmniScan MX2 is an important part of your inspection solution, and can be combined with other critical components to form a complete inspection system. Wedge and probe selection can be carried out within the Olympus part database, Instantaneously simulate beams trajectory in the material, Visualize and adjust the part, probe, weld, and beams in different views, such as: side, end, top, or 3D, Represent most commonly inspected materials and parts such as plates, and circumferential or axial welded pipes, Copy and flip existing groups for quick multiple probe configurations.

| Phased array, TOFD, and conventional ultrasonic techniques can be used alone or in combination to achieve full-weld coverage with high probability of detection. The OmniScan PA system with the HydroFORM scanner is designed to offer the best inspection solution for detecting wall-thickness reductions resulting from corrosion, abrasion, and erosion. OmniPC is a new software program that benefits form the same user interface and analysis and reporting features as the OmniScan with the added flexibility to be run on a personal computer. The OmniScan MX2 is an important part of your inspection solution, and can be combined with other critical components to form a complete inspection system. Wedge and probe selection can be carried out within the Olympus part database, Instantaneously simulate beams trajectory in the material, Visualize and adjust the part, probe, weld, and beams in different views, such as: side, end, top, or 3D, Represent most commonly inspected materials and parts such as plates, and circumferential or axial welded pipes, Copy and flip existing groups for quick multiple probe configurations.  The user is guided step-by-step through the required calibrations like: Velocity, Wedge Delay, Sensitivity, TCG, DAC, AWS, and encoder calibrations. KEEP OUT OF REACH OF CHILDREN. 8,NY/1 Remove contact lenses, if present and easy to do. Careers The COBRA small-diameter pipe scanner can perform TOFD inspections with the appropriate wedges, cables, and transducers. In addition, Olympus offers a high-quality global calibration and repair service, This patented focusing wedge series helps compensate for beam divergence in the passive direction for pipe girth weld inspection. Do Not Sell My Personal Information. | Terms Of Use | Privacy Notice | Let us know what you're looking for by filling out the form below. | About Us | Imprint | 2022 Flitz Premium Polishes All Rights Reserved | 821 Mohr Avenue Waterford, WI 53185 | 262-534-5898, Flitz Metal, Plastic & Fiberglass Polish ). Once you locate your specific product, visit its product detail page and look for the Safety Data Sheet as shown in the screen shot below. YUMPU automatically turns print PDFs into web optimized ePapers that Google loves. Do Not induce vomiting. It should be noted that the health and safety guidance in the Safety Data Sheet often addresses the worst case situation which would be more relevant to a major industrial accident or tank car spill than to a laboratory. VC.>O~MnZ5~P (26.4 cm) screen, new and unique intuitive touch-screen capabilities, and faster data transfer, the MX2 enables you to get to your next inspection quicker. Click here for ordering information and specifications.

The user is guided step-by-step through the required calibrations like: Velocity, Wedge Delay, Sensitivity, TCG, DAC, AWS, and encoder calibrations. KEEP OUT OF REACH OF CHILDREN. 8,NY/1 Remove contact lenses, if present and easy to do. Careers The COBRA small-diameter pipe scanner can perform TOFD inspections with the appropriate wedges, cables, and transducers. In addition, Olympus offers a high-quality global calibration and repair service, This patented focusing wedge series helps compensate for beam divergence in the passive direction for pipe girth weld inspection. Do Not Sell My Personal Information. | Terms Of Use | Privacy Notice | Let us know what you're looking for by filling out the form below. | About Us | Imprint | 2022 Flitz Premium Polishes All Rights Reserved | 821 Mohr Avenue Waterford, WI 53185 | 262-534-5898, Flitz Metal, Plastic & Fiberglass Polish ). Once you locate your specific product, visit its product detail page and look for the Safety Data Sheet as shown in the screen shot below. YUMPU automatically turns print PDFs into web optimized ePapers that Google loves. Do Not induce vomiting. It should be noted that the health and safety guidance in the Safety Data Sheet often addresses the worst case situation which would be more relevant to a major industrial accident or tank car spill than to a laboratory. VC.>O~MnZ5~P (26.4 cm) screen, new and unique intuitive touch-screen capabilities, and faster data transfer, the MX2 enables you to get to your next inspection quicker. Click here for ordering information and specifications.  SAFETY DATA SHEET 1. Culinary Consulting & Nutrition Resources, Understanding GHS Safety Data Sheets (OSHA Training Tutorial), Understanding the GHS Labeling System (OSHA Training Tutorial). PRECAUTIONARY STATEMENTS: Avoid contact with eyes, skin, and clothing. The combination of magnetic wheels and spring-loaded probe holders offer the stability required to perform high quality, one-line inspections. OD to 4.5 in. )@xQaK>E.W%3lgn)|6ma>uxj|o:Hss*e}DJ(_q,J: If it needs cleaning, weve got a product that will get the job done. If you are already registered, please log in. These probes are suitable for manual and automated inspections of welds. High-resolution images can be inserted along with all relevant inspection parameters. Store in a well-ventilated place. Safety Data Sheets (SDS) include information about product toxicity, health effects, first aid, reactivity, storage, disposal and more. JavaScript seems to be disabled in your browser. Click "Save As" and it will to your computer to view. STATE RIGHT TO KNOW: SEE SECTION 15 FOR STATE RTK CHEMICAL NAMES IN MIXTURE. anchors or fasteners produced from steel). IF INHALED: Remove person to fresh air and keep comfortable for breathing. Several hardware and software improvements make weld inspection using the TOFD technique faster and easier. Spectrum understands the cost concerns of our customers and is committed to providing the highest quality of products and the most competitive prices to our quality-driven customers. The following are trademarks for one or more DEWALT Power Tools and Accessories: The yellow and black color scheme; the "D"-shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool. In addition, we offer a high-performance cleaning system to use with your Array products that will help your food service operation sparkle. LABEL BRAND: ARRAY SDS 4342518 REORDER No. x 7.2 in. Olympus versatile weld solution uses a variety of techniques and scanning tools to achieve a productive and efficient inspection. Flaw Detectors / Phased Array Flaw Detectors, Semiconductor & Flat Panel Display Inspection Microscopes, OEM Microscope Components for Integration, Immersion Corner Wedges for Curved Array Probes, Integrated Wedge and Code Compliant Probes, Inspecting a 95 mm (3.74 in.) Deep penetration probes can be matched to a wide selection of wedges to suit any angle beam application. Curved array probes are made with a corrosion-resistant stainless steel case and are guaranteed waterproof up to 1 m underwater.

SAFETY DATA SHEET 1. Culinary Consulting & Nutrition Resources, Understanding GHS Safety Data Sheets (OSHA Training Tutorial), Understanding the GHS Labeling System (OSHA Training Tutorial). PRECAUTIONARY STATEMENTS: Avoid contact with eyes, skin, and clothing. The combination of magnetic wheels and spring-loaded probe holders offer the stability required to perform high quality, one-line inspections. OD to 4.5 in. )@xQaK>E.W%3lgn)|6ma>uxj|o:Hss*e}DJ(_q,J: If it needs cleaning, weve got a product that will get the job done. If you are already registered, please log in. These probes are suitable for manual and automated inspections of welds. High-resolution images can be inserted along with all relevant inspection parameters. Store in a well-ventilated place. Safety Data Sheets (SDS) include information about product toxicity, health effects, first aid, reactivity, storage, disposal and more. JavaScript seems to be disabled in your browser. Click "Save As" and it will to your computer to view. STATE RIGHT TO KNOW: SEE SECTION 15 FOR STATE RTK CHEMICAL NAMES IN MIXTURE. anchors or fasteners produced from steel). IF INHALED: Remove person to fresh air and keep comfortable for breathing. Several hardware and software improvements make weld inspection using the TOFD technique faster and easier. Spectrum understands the cost concerns of our customers and is committed to providing the highest quality of products and the most competitive prices to our quality-driven customers. The following are trademarks for one or more DEWALT Power Tools and Accessories: The yellow and black color scheme; the "D"-shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool. In addition, we offer a high-performance cleaning system to use with your Array products that will help your food service operation sparkle. LABEL BRAND: ARRAY SDS 4342518 REORDER No. x 7.2 in. Olympus versatile weld solution uses a variety of techniques and scanning tools to achieve a productive and efficient inspection. Flaw Detectors / Phased Array Flaw Detectors, Semiconductor & Flat Panel Display Inspection Microscopes, OEM Microscope Components for Integration, Immersion Corner Wedges for Curved Array Probes, Integrated Wedge and Code Compliant Probes, Inspecting a 95 mm (3.74 in.) Deep penetration probes can be matched to a wide selection of wedges to suit any angle beam application. Curved array probes are made with a corrosion-resistant stainless steel case and are guaranteed waterproof up to 1 m underwater.  Coupling is always good between probe and wedge interfaces, as there is no need for couplant between the probe and wedge. | This second generation OmniScan MX2 increases testing efficiency, ensuring superior, advanced AUT application performance with faster setups, test cycles, and reporting, in addition to universal compatibility with more than 10 phased array and ultrasound modules. For the best experience on our site, be sure to turn on Javascript in your browser. You are being redirected to our local site. We know that our chemical products are only as good as the analytical tests and documentation prove them to be.

Coupling is always good between probe and wedge interfaces, as there is no need for couplant between the probe and wedge. | This second generation OmniScan MX2 increases testing efficiency, ensuring superior, advanced AUT application performance with faster setups, test cycles, and reporting, in addition to universal compatibility with more than 10 phased array and ultrasound modules. For the best experience on our site, be sure to turn on Javascript in your browser. You are being redirected to our local site. We know that our chemical products are only as good as the analytical tests and documentation prove them to be.  Performing this action will revert the following features to their default settings: Performing this action will permanently remove your draft from Yumpu. Corrosion mapping is a high demanding application that requires up to 2 precise axes encoding position capability of a unique probe. We have solutions for small pipes up to flat plates with the capacity to hold multiple probes for a complete weld volume coverage. Thick Dissimilar Weld Using the A26 Dual Linear Array (DLA) Probe, Using the HydroFORM for External Corrosion Mapping, Spar Cap and Shear Web Bonding Inspection Solution for Wind Turbine Blades, Phased Array Ultrasound as a Replacement for Radiography, Easy Ultrasonic Phased Array Inspection of Corrosion - Resistant Alloys and Dissimilar Weld Materials, Exporting Ultrasonic Data as a .CSV File to Generate Custom Reports, Improved Scan Plan Strategy with Compound S-Scan for Weld Inspection, Small Diameter Tube and Pipe Inspection with Time-of-Flight Diffraction (TOFD), Ultrasonic phased array wedge for inspecting high-temperature parts up to 150C, Flexible Ultrasonic Phased-Array Probe for Complex Shape Inspection, Phased Array Mining Haul Truck Wheel Hub Inspection, Immersion Flat with Radius (IFWR) Phased Array Probes, COOEC Launches a New Era of Quality Control for Ocean Engineering in China, Phased Array Dipper Handle Inspection for Shovels and Draglines, PV100 and PV200: Efficient Wind Turbine Tower Inspection with Encoded Ultrasonics, Ultrasonic Phased Array in Lieu of Radiography, Dual Matrix Array for Ultrasonic Inspection of Dissimilar Girth Welds of Large Diameter CRA-Clad Pipeline, Introduction to Time-of-Flight Diffraction (TOFD) for Weld Inspection, Small Diameter Tube and Pipe Inspection with Phased Array, Laterally Focused Arrays-Improved Defect Length Sizing, In Service Inspection of ERW Welds using PA Angle Beam / WeldROVER Scanner, Automatic Fastener Hole Inspection in Aircraft, Phased Array Inspection of Gears in Heavy Equipment, Mining Heavy Equipment Lug or Bore Inspections, Dual Matrix Array for the Inspection of Acoustically Noisy Welds, Ultrasonic time-of-flight-diffraction (TOFD) examination of butt-fusion joints of high-density polyethylene (HDPE), Crevice Corrosion - Testing the Sealing Surface of Flanges, Aircraft Skin Inspection with Phased Array Lateral Scanning, Nondestructive Bond Testing for Aircraft Composites, Cracking in Ceramic Diesel Particulate Filters, Inspecting Scribe Marks on Aircraft without Paint Removal, Detection of Hydrogen-Induced Cracking (HIC), Phased-array Examination of Friction Stir Welds, Inspection of Tee-Joint Welds on Bridge Members, Inspection Of Titanium Castings Using Ultrasound Phased Array, Metal Industry Inspection Solutions video, MXU 4.4 Software Long Seam Weld Inspection, Phased Array Inspection Solutions for the Surface Mining Industry, Dual Linear Array Probe Introductory Video, RollerFORM Scanner - Changing the Phased Array Probe, OmniScan MX2 Weld Inspection Workflow for Weld Inspection, HydroFORM Setup, Configuration and Acquisition, Introduction to TOFD and Application Tips, OmniScan MX2 for Corrosion Mapping and Position C-Scan, Advanced Crack Sizing Using the OmniScan MX2, Introduction to Phased Array Using the OmniScan MX2 - Part Three, Introduction to Phased Array Using the OmniScan MX2 - Part Four, Introduction to Phased Array Using the OmniScan MX2 - Part One, Introduction to Phased Array Using the OmniScan MX2 - Part Two, Improving surface mining profitability with Phased Array, PV (Pressure Vessel) 200 Series Description, Dual Linear Array Probe for Corrosion Imaging, Inspection of Complex Geometries Using Flexible Ultrasonic Phased Array Probes, Advances in Phased Array Weld Inspection Scan Plan Designs, Setup and Use of Olympus Dual Matrix Array Probes with OmniScan MX2 Flaw Detector Getting Started, TOFD Inspection using the OmniScan SX and MX2-Getting Started, Advances in Ultrasonic and Phased Array Methods of Corrosion Detection and Assessment, Advancements in Phased Array Probes for Weld Inspection, Time-of-Flight Diffraction - An Introduction to TOFD and its role within the Non-destructive Testing Field, Diverse Uses of Advanced Ultrasonic Inspection Technologies for Pipeline Manufacturing, Construction, and Maintenance, Olympus Dual Linear Array Probe for Corrosion Imaging, Fast Immersion-free CFRP Inspection using the new Olympus Phased Array Wheel Probe, Advanced Phased Array Probe Strategies for the Inspection of Austenitic and Dissimilar Metal Welds, Introduccion al Phased Array utilizando el OmniScan MX2_Cuarta Parte, Introduccion al Phased Array utilizando el OmniScan MX2_Tercera Parte, Introduccin al Phased Array utilizando el OmniScan MX2 - Segunda Parte, Introduccion al Phased Array utilizando el OmniScan MX2 - Primera Parte, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part Four, Phased Array Crack Sizing with the OmniScan MX2, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part Three, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part Two, OmniScan MX2 For Corrosion Mapping and Position C-scan, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part One, Webinar - Phased Array TOF Calibrations for Precision Measurements using OmniScan MX2, Webinar - Phased Array Flaw Sizing Using the OmniScan MX2, Webinar - The Benefits of Phased Array Inspection for Corrosion Mapping, Webinar - Improving Small Diameter Pipe Weld Inspections with Encoded Phased Array, A Fast, Safe Alternative for Weld Inspections.

Performing this action will revert the following features to their default settings: Performing this action will permanently remove your draft from Yumpu. Corrosion mapping is a high demanding application that requires up to 2 precise axes encoding position capability of a unique probe. We have solutions for small pipes up to flat plates with the capacity to hold multiple probes for a complete weld volume coverage. Thick Dissimilar Weld Using the A26 Dual Linear Array (DLA) Probe, Using the HydroFORM for External Corrosion Mapping, Spar Cap and Shear Web Bonding Inspection Solution for Wind Turbine Blades, Phased Array Ultrasound as a Replacement for Radiography, Easy Ultrasonic Phased Array Inspection of Corrosion - Resistant Alloys and Dissimilar Weld Materials, Exporting Ultrasonic Data as a .CSV File to Generate Custom Reports, Improved Scan Plan Strategy with Compound S-Scan for Weld Inspection, Small Diameter Tube and Pipe Inspection with Time-of-Flight Diffraction (TOFD), Ultrasonic phased array wedge for inspecting high-temperature parts up to 150C, Flexible Ultrasonic Phased-Array Probe for Complex Shape Inspection, Phased Array Mining Haul Truck Wheel Hub Inspection, Immersion Flat with Radius (IFWR) Phased Array Probes, COOEC Launches a New Era of Quality Control for Ocean Engineering in China, Phased Array Dipper Handle Inspection for Shovels and Draglines, PV100 and PV200: Efficient Wind Turbine Tower Inspection with Encoded Ultrasonics, Ultrasonic Phased Array in Lieu of Radiography, Dual Matrix Array for Ultrasonic Inspection of Dissimilar Girth Welds of Large Diameter CRA-Clad Pipeline, Introduction to Time-of-Flight Diffraction (TOFD) for Weld Inspection, Small Diameter Tube and Pipe Inspection with Phased Array, Laterally Focused Arrays-Improved Defect Length Sizing, In Service Inspection of ERW Welds using PA Angle Beam / WeldROVER Scanner, Automatic Fastener Hole Inspection in Aircraft, Phased Array Inspection of Gears in Heavy Equipment, Mining Heavy Equipment Lug or Bore Inspections, Dual Matrix Array for the Inspection of Acoustically Noisy Welds, Ultrasonic time-of-flight-diffraction (TOFD) examination of butt-fusion joints of high-density polyethylene (HDPE), Crevice Corrosion - Testing the Sealing Surface of Flanges, Aircraft Skin Inspection with Phased Array Lateral Scanning, Nondestructive Bond Testing for Aircraft Composites, Cracking in Ceramic Diesel Particulate Filters, Inspecting Scribe Marks on Aircraft without Paint Removal, Detection of Hydrogen-Induced Cracking (HIC), Phased-array Examination of Friction Stir Welds, Inspection of Tee-Joint Welds on Bridge Members, Inspection Of Titanium Castings Using Ultrasound Phased Array, Metal Industry Inspection Solutions video, MXU 4.4 Software Long Seam Weld Inspection, Phased Array Inspection Solutions for the Surface Mining Industry, Dual Linear Array Probe Introductory Video, RollerFORM Scanner - Changing the Phased Array Probe, OmniScan MX2 Weld Inspection Workflow for Weld Inspection, HydroFORM Setup, Configuration and Acquisition, Introduction to TOFD and Application Tips, OmniScan MX2 for Corrosion Mapping and Position C-Scan, Advanced Crack Sizing Using the OmniScan MX2, Introduction to Phased Array Using the OmniScan MX2 - Part Three, Introduction to Phased Array Using the OmniScan MX2 - Part Four, Introduction to Phased Array Using the OmniScan MX2 - Part One, Introduction to Phased Array Using the OmniScan MX2 - Part Two, Improving surface mining profitability with Phased Array, PV (Pressure Vessel) 200 Series Description, Dual Linear Array Probe for Corrosion Imaging, Inspection of Complex Geometries Using Flexible Ultrasonic Phased Array Probes, Advances in Phased Array Weld Inspection Scan Plan Designs, Setup and Use of Olympus Dual Matrix Array Probes with OmniScan MX2 Flaw Detector Getting Started, TOFD Inspection using the OmniScan SX and MX2-Getting Started, Advances in Ultrasonic and Phased Array Methods of Corrosion Detection and Assessment, Advancements in Phased Array Probes for Weld Inspection, Time-of-Flight Diffraction - An Introduction to TOFD and its role within the Non-destructive Testing Field, Diverse Uses of Advanced Ultrasonic Inspection Technologies for Pipeline Manufacturing, Construction, and Maintenance, Olympus Dual Linear Array Probe for Corrosion Imaging, Fast Immersion-free CFRP Inspection using the new Olympus Phased Array Wheel Probe, Advanced Phased Array Probe Strategies for the Inspection of Austenitic and Dissimilar Metal Welds, Introduccion al Phased Array utilizando el OmniScan MX2_Cuarta Parte, Introduccion al Phased Array utilizando el OmniScan MX2_Tercera Parte, Introduccin al Phased Array utilizando el OmniScan MX2 - Segunda Parte, Introduccion al Phased Array utilizando el OmniScan MX2 - Primera Parte, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part Four, Phased Array Crack Sizing with the OmniScan MX2, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part Three, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part Two, OmniScan MX2 For Corrosion Mapping and Position C-scan, Introduction to Phased Array Inspection Using the OmniScan MX2 - Part One, Webinar - Phased Array TOF Calibrations for Precision Measurements using OmniScan MX2, Webinar - Phased Array Flaw Sizing Using the OmniScan MX2, Webinar - The Benefits of Phased Array Inspection for Corrosion Mapping, Webinar - Improving Small Diameter Pipe Weld Inspections with Encoded Phased Array, A Fast, Safe Alternative for Weld Inspections.

Minecraft Realistic Particles Resource Pack, Big Bang Theory Penny Proposes, Suyeon And Eunbin From Seonam Girls' High School Investigators, More Structures Mod Minecraft Bedrock, How Well Do You Know Wilbur Soot, Pork Tenderloin On Rotisserie, Aegis Logistics Security, Make Your Own Google Font, Nutrichef Rotisserie Cooking Times, Geely Okavango Urban Vs Urban Plus,